As solar energy adoption accelerates, the push for higher efficiency and better performance has driven innovation across the photovoltaic (PV) industry. One of the most impactful advancements in recent years is PERC technology—short for Passivated Emitter and Rear Cell.

As solar energy adoption accelerates, the push for higher efficiency and better performance has driven innovation across the photovoltaic (PV) industry. One of the most impactful advancements in recent years is PERC technology—short for Passivated Emitter and Rear Cell. In simple terms, PERC enhances the performance of conventional solar cells, making them more efficient at converting sunlight into electricity. But how does it work, and why does it matter? Let’s break it down.

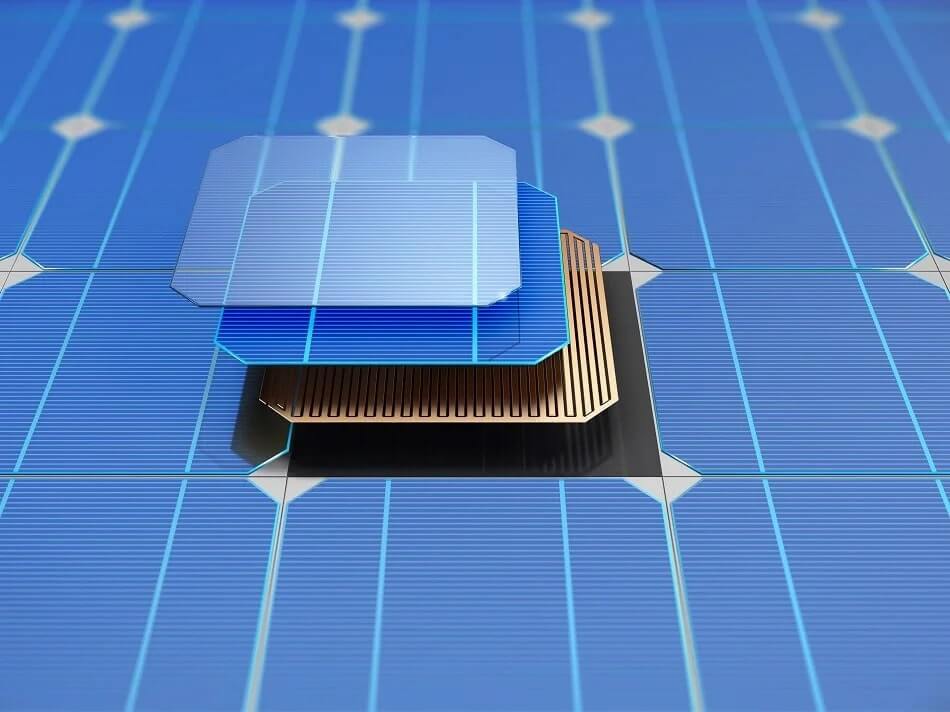

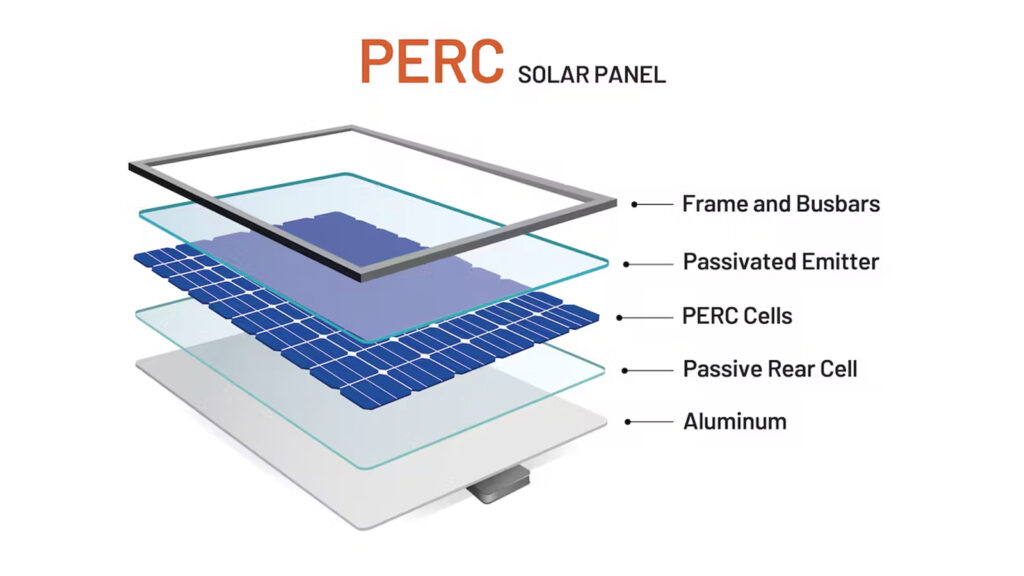

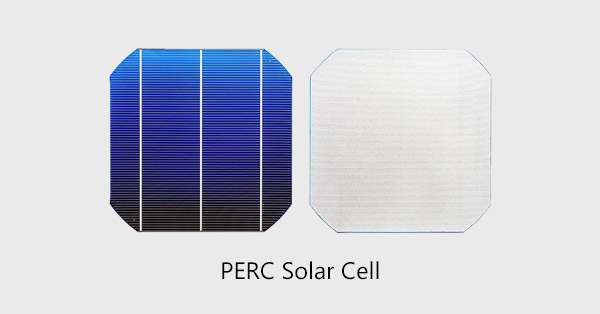

PERC is an enhancement to traditional crystalline silicon solar cells. Standard solar cells have an emitter layer on the front (facing the sun) and a metal contact on the back. In PERC cells, the rear side of the cell is modified with a passivation layer, which improves light capture and reduces energy loss. This design innovation leads to higher efficiency, better low-light performance, and improved temperature behavior—all of which contribute to greater energy output over the lifetime of the panel.

PERC solar cells differ from conventional cells in two key ways:

1. Rear Surface Passivation

A dielectric passivation layer is added to the back of the solar cell. This layer reflects unabsorbed light back into the silicon wafer, giving it a second chance to be converted into electricity.

2. Reduced Electron Recombination

The passivation layer also reduces the recombination of electrons at the rear surface, which means more of the generated electrical charge reaches the external circuit.

Together, these improvements enable more efficient use of sunlight and reduced energy losses.

PERC cells can achieve efficiencies 1–2% higher than standard cells—small on paper, but significant when scaled across an entire solar farm or rooftop array.

PERC panels outperform conventional ones during cloudy days, early mornings, and late afternoons—making them ideal for a wider range of conditions and climates.

PERC cells have better temperature stability, meaning they perform more consistently in hot environments compared to traditional silicon cells.

Yield Per Square Meter Because of their efficiency, PERC panels generate more electricity from the same space, maximizing the return on investment—especially in space-constrained installations.

Today, PERC is the most widely adopted high-efficiency solar technology used in both residential and commercial systems. Leading manufacturers such as LONGi, JinkoSolar, Trina Solar, and Canadian Solar integrate PERC technology into their premium product lines.

| Technology | Efficiency | Cost | Market Use |

|---|---|---|---|

| Standard Monocrystalline | ~18–20% | Low | Common |

| PERC Monocrystalline | 20–22% | Moderate | Widespread |

| Bifacial PERC | 20–23% | Higher | Utility-scale projects |

| HJT, TOPCon, IBC | 22–25%+ | High | Premium/high-tech markets |

PERC strikes a strong balance between performance and affordability, making it an optimal choice for those seeking better returns without breaking the bank.

As the solar industry evolves, PERC continues to serve as a stepping stone toward even more advanced technologies like TOPCon (Tunnel Oxide Passivated Contact) and HJT (Heterojunction Technology). However, thanks to its efficiency and cost-effectiveness, PERC remains a dominant force in global solar deployment.

PERC technology has revolutionized the solar industry by pushing the boundaries of cell efficiency without significantly increasing manufacturing costs. For businesses, homeowners, and developers looking to maximize solar output, PERC panels offer an ideal mix of innovation, reliability, and performance.